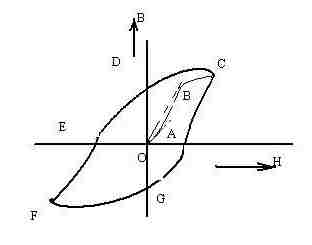

Magnetizing Curve of Ferrite

As shown in this graph, it contains three sections. Its initial Susceptibility uo=dB/dH, and is expressed by the reversible line in section one, where the shifting of Bloch Wall is reversible. When the Intensity of Magnetization H decreases, Magnetic Induction decreases along the reversible line.

When H increases, Bloch Wall shifting increases and Magnetic Induction B increases rapidly by the reversible line. This second section AB is irreversible, i.e., when H decreases, B decreases by the other line. In this section, you can observe the Barkhausen Effect, i.e., put a stethoscope/receiver near the Ferrite material and you will hear the special noise when the external magnetic field changes.

The third section has a tender slope and is reversible. At point B, umax= B/H.

When H changes back and forth in a cycle, the magnetic hysteresis loop CDEFGC is formed. In the graph, OD equals the residual magnetism Br. OE equals the coercive force Hc. The area of this loop equals the energy loss in the form of heat within the unit volume of the Ferrite during the magnetic cycle.

Magnetism of the Atom

Every element has the Magnetic Moment due to the rotation of its electrons on the inner and outer orbits. Every spinning electron has the potential energy of one Bohr Magneton.

1 Bohr Magneton = 9.27x10-24 Amp.m2

Depending on the direction of the rotation, the Magnetic Moment can be positive or negative. Those electrons of opposite spinning direction negate each other and hence the overall Magnetic Moment equals zero. When external magnetic field is applied, one electron will be attracted while others being repelled and consequently change its orbit to a higher energy level. When the external magnetic field disappears, the energy level will come down to normal.

When the magnetizing direction inside the material is in opposition to the external magnetic field, this kind of material belongs to the category of diamagnetism. The flux line of the external magnetic field will be dispersed by the electrons in the saturated orbits of these material. This kind of material include those that are called excellent electric insulators such as crystal, diamond and glass etc.. When the magnetizing direction inside the material is in sync with the external magnetic field, this kind of material belongs to the category of para-magnetism. The external magnetic field can excite a few electrons to move into the neighboring orbit of higher energy. This will cause the spin transition of that electron. The flux line of the external magnetic field will experience concentration by the electrons inside these kind of material.

Only four elements in the periodic table, i.e., Fe, Ni, Co and Gd show the most para-magnetism and can be made into permanent magnet. Among them, Fe is the most important element in magnetism and hence referred to as ferro-magnetism. Atoms of these elements has stronger magnetic dipole moment and can bond to form the magnetic domain, i.e., spontaneous magnet. The area between the magnetic domain is called Bloch Wall, around which the electron change its spinning direction gradually.

Two same poles, when placed 1 cm apart and generate the push force of 1 dyne, these two poles are called unit pole. The intensity of magnetization(H) at 1 cm away from the unit pole equals 1 Oersted.

Anisotropic (orientation) - The material has a preferred direction of magnetic field.

Coercive Force - The demagnetizing force, in oersteds, required to reduce the residual induction, Br, of a fully magnetized magnet to zero.

Curie Temperature - Temperature at which a material loses its magnetic properties. The Curie temperature of Fe is 770 oC, Co is 1120 oC and Ni is 358 oC.

Gauss - Unit of measure of magnetic induction, B, or flux density in the CGS system.

Intrinsic Coercive Force, Hci - Oersted measurement of the material's inherent ability to resist self-demagnetization.

Isotropic (non-oriented) - The material has no preferred direction of magnetic orientation, which allows magnetization in any direction.

Magnetic Induction, B - Flux per unit area of a section normal to the direction of the magnetic path. Measured in gauss.

Maximum Energy Product, BHmax - The maximum product of (BdHd) which can be obtained on the demagnetization curve.

Maximum Operating Temperature - The maximum temperature of exposure that a magnet can forego without significant long-range instability or structural changes.

Magnetic Flux - The number of magnetic lines crossing the given area.

Magnetic Induction - The density of Magnetic Flux per unit area.

North and South Pole - Each magnet is built in with a North pole and a south pole. If you break a magnet into a smaller piece, a new pair of N and S poles will ocur. N pole attracts the geographic North Pole and S pole seeks the South Pole of the Earth.

Residual Induction - Flux density, measured in gauss, of a magnetic material after being fully magnetized in a closed circuit.

Q. What is "Neodymium"?

Neodymium (Nd) is an element. In the periodic table, Nd is found in the lanthanide, or "Rare Earth" section. Nd is only one of the necessary components in an NdFeB magnet. The other important parts are: Fe or iron. and a trace amount of B or boron. Neodymium magnets are smaller, stronger and most cost-effective in application. The most powerful magnets available today are the Rare Earths types. Of the Rare Earths, Neodymium-Iron-Boron types are the strongest. On a cost-per-pound basis, Neodymium magnets seem costly. However, on a cost per BHmax basis, they are very efficient in cost. By using the Neodymium magnet, the entire machine/equipment that it goes into can be minimized, yielding cost savings that favor its usage.

Q. What metals are magnets attracted to?

Magnets attract to ferrous metals such as iron, nickel, cobalt, certain steels and other alloys. Brass, aluminum, copper, and most stainless steels, however, are non ferrous.

Q. What are magnetic fields?

Magnetic fields are moving electrical charges that attract and repel one another.

Q. Why is the grade of a magnet important?

The grade of a magnet (N35, N38, N40, N45, etc) is important because it specifies the quality of material used to construct the magnet. Usually the higher the grade of the magnet, the greater the magnetic strength

Q. Can the magnet be machined?

Most magnets can be machined with special equipment. Hard magnet materials as opposed to the flexible rubber magnets are extremely difficult to machine and should be machined using diamond tools or waterjet cutting/grinding machine. Machining should be done in the unmagnetized state as far as possible. Yet, it is best to avoid machining the hard magnet materials unless necessary.

Q. Why is the Br value usually different from the Gauss reading of a magnet surface?

The Br value is measured under closed circuit conditions. In practice, you will measure a field that is less than Br value close to the surface of the magnet. The actual measurement will depend on whether the magnet has any steel attached to it, how far away from the surface you make the measurement, and the size of the magnet.

Q. What is induction?

Induction is a term used to define how changing magnetic fields generate electric currents. This process happens when copper is exposed to changing magnetic fields, it then "induces" an electrical current.

Q. What is an electromagnet?

An electromagnet is a magnet with magnetic force that is generated by passing an electrical current through a copper wire when the wire is wound into a coil. An electromagnet can be made stronger simply by adding a stronger electrical current to the coil.

Please contact us at:

Office phone: (561)637-8129 Mobile phone:(561)306-9894

Toll Free Fax: (866)393-5756 Email address:amerimagnet@yahoo.com

COPYRIGHT of American Magnetic Engineering. ALL RIGHTS RESERVED